The 2023/24 season gave us many reasons to be proud. However, it was also extremely difficult and, at times, frustrating and disappointing.

Pre-harvest drought slashed coffee yields by half and, with ongoing global price volatility, fuelled unprecedented competition across the Mt. Elgon region. Extended rains delayed coffee drying and export, and when we did ship the disruption in the Suez kept our coffee on the sea for months longer. Hitting 50% of our volume target obviously hurts our financial position and coffees landing very late affects our clients.

Despite all of this, we received only understanding and support from Falcon Specialty, our longstanding roaster partners (especially Square Mile, Father's Coffee Roastery and KAL Coffee) and our lender Rabo Foundation.

We had tried to be prepared for disruption. Prior to last season, we built new coffee driers and improved our water treatment system. We also massively scaled up our experimental coffee processing techniques, receiving excellent feedback. We were visited by more roasters, funders and new partners than ever before. This encouragement keeps us going.

As an impact-driven business, we must make commercially sound decisions or our social activities will never be sustainable. We continued our farmer trainings, expanded our zero-interest loan service, and continued our pilot to encourage farmers to receive digital payments rather than cash. These initiatives were vital investments to maintain loyalty and improve farmer resilience.

More than ever, however, we worry our efforts may be undermined by factors beyond anyone's control. Last year's drought enabled pests to thrive at higher altitudes, damaging coffee. We worry about the message this sends to farmers we train in good agricultural practices. What incentive do they have to focus on quality if their work can be undone just like that?

The only way to combat these challenges is for us to keep innovating. Made possible by significant new investments from Fathers’ Coffee Roastery (supported by a matching grant from the Czech Development Agency), Rabo and KAL, we are now taking a major leap forward by establishing a state-of-the-art green coffee optical sorting facility and quality lab. This will radically change our approach to quality enhancement by eliminating significant pre-export bottlenecks and allowing rapid feedback to our processing team and farmers.

Most importantly, and despite everything, our farmers supported us by supplying good quality coffee. Their biggest request to us? Be ready to buy more coffee next season.

Dana, Michael & Shak

We exported our coffee at USD $7.58 / kg (exclusively to Falcon Specialty)

Our farmers earned USD $3.71 / kg (49% of our export price)

There was intense local competition due to volatility in the international market and limited coffee available domestically. It's difficult to determine how much farmers earned through other sales channels. Some traders offered higher prices, for short periods of time, but typically buying only small volumes.

Despite higher prices being available, our surveys indicate that our farmers delivered 60% of their total production to us (comparable to previous years). When asked why they deliver to us loyally, farmers responded that they value the additional services that only we provide.

Farming Households Supplying Cherries

Paid to Farmers

People Employed

60 kg Bags Produced

Coffee Cherries

Export Green Coffee

Roasted Coffee

Espresso Shots

Partner Producers

Total Bags Exported

Increase in Export

FARMERS

Grow & Harvest Coffee

THE COFFEE GARDENS

See Next Page

ROASTERS COFFEE & SHOPS

Roasting, Wholesale & Retail

CONSUMERS

Drink & Enjoy

84 Coffee Trees

6 Farmers Picking for 6 Hours

1 Person Buying, Weighing

420 kg of Red Cherry

11 People Carrying Coffee

in 30-50 kg Bags

1 hour, 700 Vertical Metres Down the Mountain

4 People Weighing, Sorting &

Floating (30 min)

Pulping (30 min)

Fermentation (40 - 140 hours)

840 l of Water, 1/4 l of Fuel

3 people Sorting and Turning

(2-3 weeks)

Transport from Bukyabo Washing Station to the Mbale Drying Yard:

45 km, 1 Truck, 2 Hours

2 People Loading and Unloading

2 People Weighing, Turning &

Final Hand Sorting

Hulling, Grading, Gravity Table + Colour Sorter (1 day)

2 People Preparing & Cupping Samples (2 days)

1 Person Printing Labels

1 GrainPro Bag

1 Gunny Bag

2 Inspectors

6 Different Forms (1/2 day)

3 Export Observers (1/2 day)

Transport to Mombasa: 1,100 km

On the Sea (2 months)

In times of intense market volatility coupled with low yields, quality is our lifeline. It allows us to earn enough to pay farmers premium prices, cover our costs and invest in agricultural, social, and environmental initiatives.

In previous seasons, we tried out different processing experiments. This season, we massively scaled up the most exciting and in-demand processing methods, while still experimenting with new techniques and fermentation methods. For the first time, we received large orders from roasters at the beginning of the season for specific profiles, which was a huge opportunity (with a lot of pressure!).

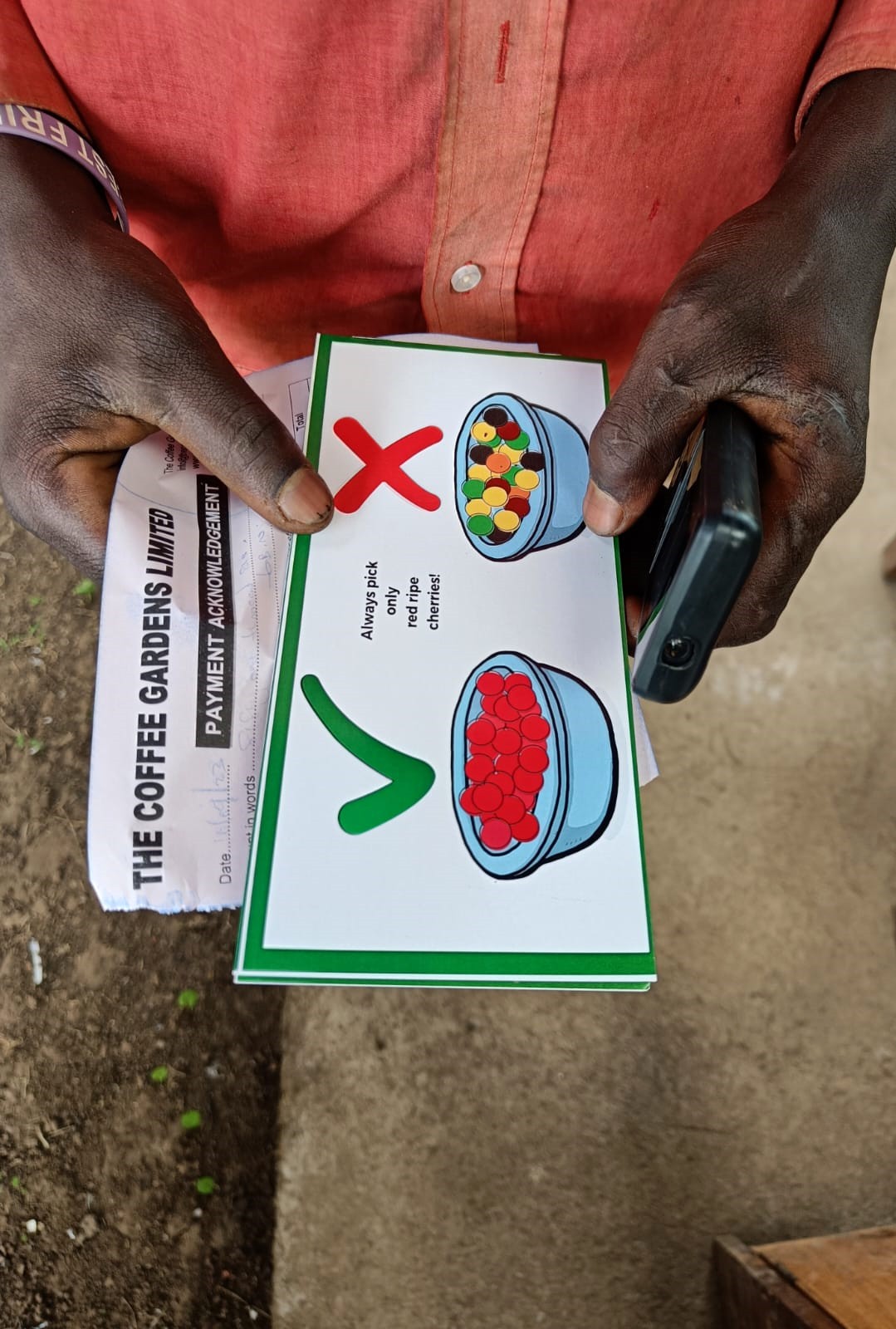

Ideally, exceptional coffee starts with 100% fresh, ripe cherries. With heavy competition and volatile prices, it's not always easy to incentivise farmers to consistently deliver only the finest cherries. This challenge is compounded by the fact that we can have up to 16 tonnes arriving all at once, just as the sun is setting. This means our protocols for sorting at different stages have to be absolutely on point, and appropriate and realistic for the conditions. Our coffee is sorted at seven different stages prior to being fully dried. Post hulling, the final stage includes density and optical sorting that ensure only defect-free beans proceed to export.

In a single day we can receive between 200 and 16,500 kg of cherries from hundreds of farmers. Each day’s coffee is processed as a “day lot", which is processed, dried and stored separately until we cup and are ready for export preparation. Our record keeping means every step meticulously tracked for full traceability, with each day lot linked to the contributing farmers.

Last season, we produced 104 day-lots, resulting in nine micro-lots and five experimental nano-lots, showcasing our commitment to quality and innovation.

Last season marked a significant milestone for us with the establishment of a new Quality Control Lab to enhance the quality of our coffee even further. The QC Lab is being managed by our newest team member, Donald Kiima Isingoma, a CQI certified Q Grader. It serves as a crucial facility for inspecting green coffee for defects, moisture content, and adherence to Specialty Coffee Association (SCA) standards, ensuring that our coffee meets the highest quality benchmarks. Most importantly, we now have a rapid feedback loop between our processing and quality teams, which especially helps with our experiments.

The initiative also reflects our long-term vision for sustainability and education: with the QC Lab, we provide training for farmers and staff, showing them how to detect the different coffee defects and how they influence the final taste. Together, this will empower us to further improve the quality of our farmers' coffee.

Freshly picked cherries are pulped prior to a prewash, a long soak in cold mountain spring water, then a gentle 40-hour submerged fermentation. All coffee is dried on African drying beds in our solar dryers and meticulously sorted at 12 different stages before export.

Cherries are dry fermented in tanks for 100 hours. They are then pulped followed by a long soak in cold mountain spring water, then a 40-hour submerged fermentation. Followed by drying, more sorting and export.

Cherries are pulped, followed by a 40-hour dry fermentation finished with a thorough wash in cold mountain spring water. And as usual, followed by drying and sorting before export.

Skin Contact Fermentation

Freshly picked ripe cherries are first pulped then submerged in water and co-fermented with their pulps for twenty three hours. These pulps come from freshly pulped cherries and are still wet and juicy with sugars.

Cupping Notes:

White Grape, Chamomile, Brown Sugar, White Chocolate

This nanolot is named after Jackie Nafuna, our dedicated Field and Processing Officer. Jackie began her journey with us as a day labourer and we immediately could see her potential. Now, during the harvest season, Jackie supervises over 40 workers at the station, ensuring the meticulous sorting, drying and tracking of each batch of coffee. In the off-season, Jackie is tasked with training farmers and collecting data. A few years ago, Jackie purchased her own land and planted coffee, which she now delivers to the station for processing.

In Uganda, the coffee sector is highly liberalised. Although there are some rules, in reality anyone can buy any quality of coffee and offer any price. Of course there is a relationship between local prices and the NY exchange price but there are many more factors that determine local prices, such as yields, demand, speculation, harvest progress and stage of the season. There is even a huge price range on the same mountain.

Offering higher and higher prices is not the answer we've chosen. We would run out of money, make losses and see our supply chain contaminated with untraceable coffees brought from further away where prices are lower. Instead, we try to purchase "commercially", give generous bonuses and invest in off-season activities. Key to all this is price transparency. Since we started, every season we have provided farmers with contracts, buying-record booklets, receipts for every transaction and SMSs with price changes and other updates.

We are always looking for ways to ensure that there are no barriers to farmers accessing their funds and information. Last season, we made it easier for farmers to access their statement of balances and deliveries whenever they wanted and we brought in more providers of digital payments and savings to our farming community as part of our pilot to increase direct digital payments to farmers. We also tightened our rules around digital payments to reduce the likelihood of payments being sent to the wrong farmers.

Despite the challenging and short season, 68 farmers saved around $7,600 with us during the season, with some farmers choosing to save significant sums many months after the season ended. For us, this is clear evidence that our purchasing policy and practices are trusted by our farming community.

During the 2023-24 season, the average farmer delivered 576 kg (496 farmers, 285,871 kg of cherries) of coffee cherries and earned $275 (including the end-of-season bonus). This represents a 14% decrease in deliveries and a 37% decrease in earnings compared to the previous season. We also had 12% fewer farmers delivering coffee.

This significant drop in deliveries was caused by drought that devastated the later-flowering coffee trees, ending the harvest prematurely. Market volatility resulted in low prices at the beginning of the season and a 30% jump by the time the harvest was ending.

Because of this reduction in earnings, we provided bonuses and loans earlier, and made the latter available to more farmers.

Active Farmers

Female Farmers

Increase in Female Farmers

Because of the company, there is a lot of infrastructure development. I especially appreciate the toilet project because five of my children go to that school. The water piping and fixing of the taps has also helped the village. I am proud of the achievements.

During our annual origin trip, you will have a unique opportunity to take part in every stage of coffee production: harvesting in the gardens of our highest altitude farmers, trekking up and down the mountain to keep up with our "coffee runners," and getting your hands sticky and wet as you sort, float, pulp, ferment, wash, and sort again our coffees.

You'll touch, smell, and feel the differences in our processes, which include exotic fruits, 100+ hours of cherry fermentation, and other surprises. Not to mention, you'll be one of the first to cup our newest season coffees!

Can you already hear the rustle of drying coffee being turned?

Dates to be announced, please message us if you are interested in finding out more.

By working in partnership with others, we can achieve much more (and often spend less!). Over the years, we have nurtured relationships with other inspiring coffee producers, each bringing our own expertise and experiences for mutual benefit.

Here are some of their stories.

In the flatlands approaching the foothills of Mt. Elgon, Norman Mukuru has established The Coffee Yard, an impressive centre for coffee drying with a formidable reputation for high-quality naturals. Norman has perfected the art of creating a diverse range of cup profiles suited to different clients' preferences.

For the past several years, The Coffee Gardens and Norman have worked closely together to bring his exceptional coffees to market. Last season, we exported nearly 4 containers (1,158 bags) of Norman's Mt. Elgon naturals, with the majority going to Saudi Arabia and around 260 bags to the EU and UK.